Plasmatech PTFE fittings provide a leak proof seal when joining glass, quartz or PTFE tubing. Fittings and valves are supplied with Ryton® nuts installed and can be used with tubing sizes measuring from 1/8″ to 1″ or 3mm to 26mm Tube O.D. Fitting bodies are precision machined to close tolerance from premium grade, 100% virgin PTFE. Plasmatech Fittings will accept all commercially available tubing.

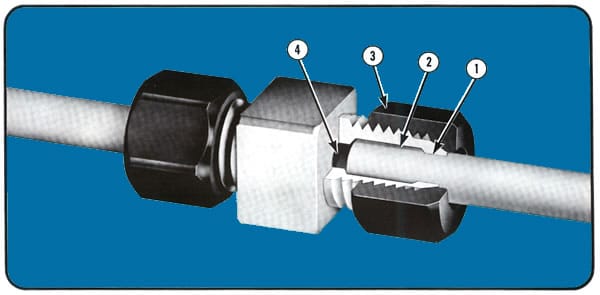

Design Features:

- Seal Surface is machined to nominal tube O.D., it expands when oversized tubing is inserted and compresses onto undersized tubing when nut is tightened.

- Internal undercut, machined to slightly larger diameter than the plus tolerance of any tubing such as quartz, permits tubing to be inserted without creating an interference fit between external threads of fitting and internal threads of fitting nut.

- Ryton nuts exert constant pressure on seal surface and tubing, maintaining a leak tight seal. Nuts can be tightened by hand or with a wrench.

- Smooth bore surfaces are designed and machined for minimum flow resistance.

- Disassembly of fitting in not required for installation, simply insert tubing and tighten nuts.

All specifications are subject to change without notice.